Driven by Technology and Personnel since Our Founding, We Are Committed to Providing Three Values

The JAMCO Group has continued to nurture its technology and personnel, generating value while constantly striving to provide better products and services and take on reforms and innovations.

The various values that JAMCO provides can be sorted into three main categories: Comfortable spaces in transport, worthwhile environmental performance, and safe operating environments. These values are the marshaling of our proprietary technologies, with which we have built trust relations with our customers through aircraft-based manufacturing and maintenance. Going forward, we will achieve sustainable growth together with our customers by continually creating new value with technology and personnel as core competencies.

The aircraft galleys and lavatories that we manufacture are installed in many mid-body and wide-body assenger aircraft operated by airlines the world over. Our own surveys show that we have approximately 40% global market share in galleys and 50% in lavatories.

The components that configure these galleys, lavatories, and other furnishings must meet strict airworthiness criteria. For example, the honeycomb panels that are the primary structural materials thereof are made of particular substances, namely carbon fiber and aramid fiber, realizing high strength and durability while being both lightweight and fire-resistant. Additionally, we pursue passenger amenity with our seats, not only in safety but also ranging from design, materials, comfort in sitting, and ease of use, to how to shift gathers in leather seat covers, providing products allowing full enjoyment of air travel. In product design and development, we consider accessibility and hygiene as well as durability and functionality and respond flexibly to even minute demands from aircraft manufacturers and airlines, thereby continually striving to maximize the value we provide to our customers.

For airworthiness certification, which is essential for aircraft to operate, three standards must be met: 1) standards for strength, structure, and performance, 2) noise standards, and 3) engine emission standards. Standard 1) is for ensuring aircraft safety, while standards 2) and 3) are for environmental compatibility. Guaranteeing airworthiness contributes not only to safety assurance, but also to environmental conservation.

JAMCO has obtained the JIS Q 9100 quality management system certification required in the aerospace field and thoroughly implements quality control to ensure airworthiness.

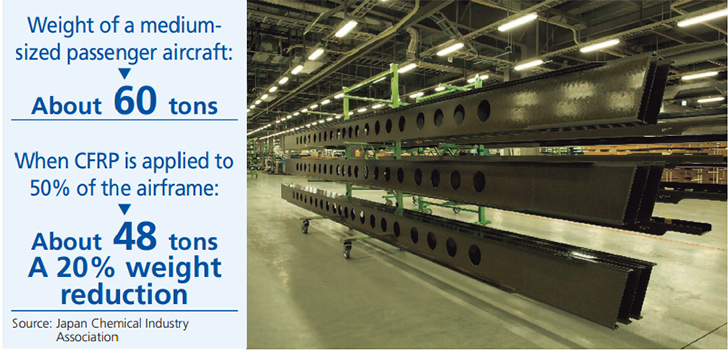

As for the environmental performance required for aircraft, reductions made to the weight of the airframe contribute to reduced fuel consumption, leading to reduced CO2 emissions. While the main raw materials for conventional aircraft are metals such as aluminum and steel, there is a growing trend of replacing these with carbon fiberreinforced plastics (CFRP), which are lighter and feature similar strength and safety.

JAMCO has independently developed a continuous molding technology using the ADP (Advanced Pultrusion) method for processing this CFRP. Since the 1990s, we have steadily built up a delivery record, promoting aircraft weight reduction while meeting airworthiness standards, thus making worthwhile environmental performance a reality.

Since our founding in 1955, we have met our customers’ wide-ranging demands as a maintenance center for small- and medium-sized aircraft, in maintenance and modification businesses. In recent times, domestic airlines have seen increasing demand for smaller passenger planes of the more fuel-efficient regional aircraft class. We are establishing systems capable of drawing on our accumulated maintenance and modification technologies to respond to such demands as periodic maintenance and modification even in the small passenger plane sector. We have carried out such work as modifications for heavy equipment or special operations on special-purpose airframes for such Japanese public agencies as the Ministry of Defense, Japan Coast Guard, Civil Aviation College, and police departments, leveraging technical partnerships with airframe manufacturers and our own proprietary technology knowhow. Additionally, the wheels of domestic airlines'

passenger aircraft are crucial components that support safety during takeoff and landing.

Our wheel maintenance business has one of the largest wheel overhaul centers in Japan, introducing the latest eco-friendly equipment and contributing to safe operations and workplace environment reform while promoting automation and labor saving. We contribute to the safety and progress of the aircraft industry by utilizing such accomplishments to further extend our technologies.

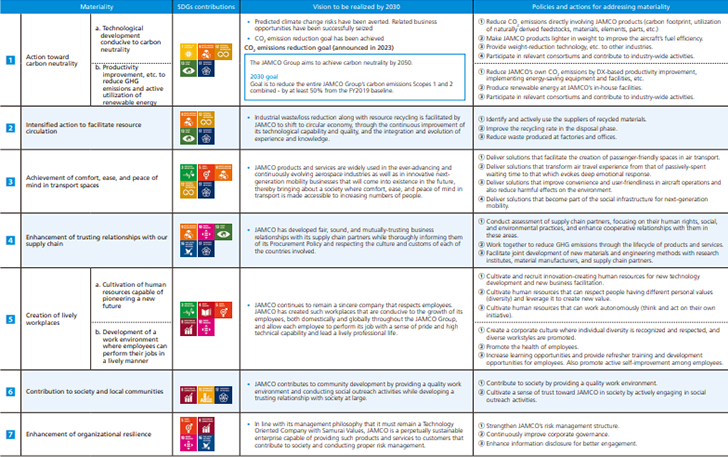

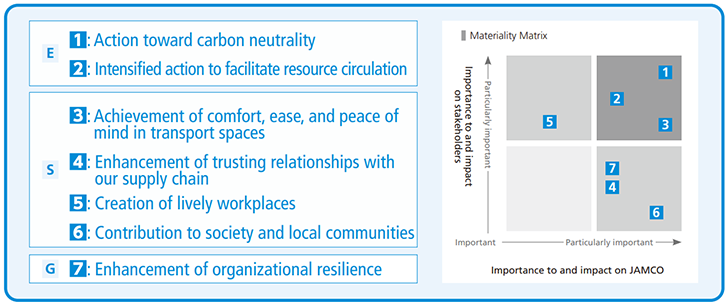

Materiality was identified while ensuring consistency with JAMCO Vision 2030, which describes the future state of society that the company will strive to bring about.

To help achieve JAMCO Vision 2030, we have set materiality targets and KPIs that are linked to our management plan.

The JAMCO Group followed the three-step process as described below in order to determine which materiality topics it should focus on, from among a wide range of sustainability issues.

- Issues relating to JAMCO’s own business activities as well as those being addressed by its customers and supply chain partners were organized to select from which the potential issues that could become JAMCO’s materiality topics, based on the international guidelines (GRI and SASB Standards) and the evaluation criteria adopted by the SDGs, ESG evaluation bodies, etc.

- The issues identified and organized in STEP 1 were evaluated from JAMCO’s own perspective as well as that of its stakeholders.

- Stakeholders’ perspective: Evaluate the issues with emphasis on constant and interactive dialogue in day-today activities.

- JAMCO’s perspective: Evaluate the issues with emphasis on JAMCO’s future vision and how crucial each of the issues would be in realizing the vision.

- Based on the evaluation result from STEP 2, a proposal of materiality topics was formulated through discussions involving working groups whose members consisted of representatives from the concerned business units and corporate departments, and reviewed by experts. The proposal was then examined and finalized by the Sustainability Promotion Board and reported to the Board of Directors.

We have identified the following seven items as materiality related to value creation:

In FY2024, under “Action toward carbon neutrality” (1), we introduced renewable energy generation facilities in the form of solar power to major production sites. Official operations have already begun at JAMCO Aircraft Interiors Corporation’s Miyazaki Factory. In FY2025, we began installing solar panels at said company’s honeycomb cores factory and the parts maintenance factory of the Aircraft Maintenance Group.

In addition, under “Creation of lively workplaces” (5) and “Enhancement of organizational resilience” (7), we progressed with the Human Rights Due Diligence Project by performing risk assessments, holding seminars for concerned individuals at each location, conducting surveys of supply chain partners (including overseas), and interviewing involved people inside the company.

We work to develop and supply products and services with due consideration to safety and quality and build relationships of greater trust with all customers. Through our sustainability and innovation activities, we work to solve social issues relating to Environment, Society, and Governance (ESG) and Sustainable Development Goals (SDGs).

In the JAMCO Vision 2030, we define a “Value Creation Corporate Group” as one that provides comfortable spaces in transport, worthwhile environmental performance, and safe operating environments in the next-generation mobility market. We conduct research and development to evolve our technology alongside innovation, incorporate it into our manufacturing, and offer products and services of value to our customers.

From in-depth basic research to application and commercialization development, our R&D efforts are split into categories according to theme and stage: basic research, applied research, and industrialization research.

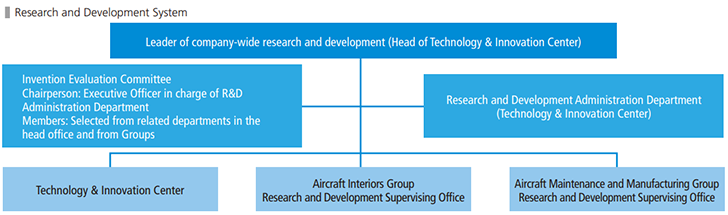

From our head office, the Technology & Innovation Center proposes and manages our company-wide technological innovation strategy, in addition to basic research, applied research and development of innovative technologies.

The Technology & Innovation Center is guided by the JAMCO Vision 2030 and its mission: “Toward a comfortable and sustainable future, taken to new heights by leveraging our technology and quality.” As the Center evolves JAMCO technology through innovation, it also works to actualize the individual technology strategies into respective initiatives and promote related activities for all companies in the JAMCO Group, thereby enabling us to become a value-providing service compny through manufacturing.

The Technology & Innovation Center oversees company-wide research and development. Under the leadership of the head of the Center, it is also responsible for R&D promotion and administration work for industrial property rights, etc.

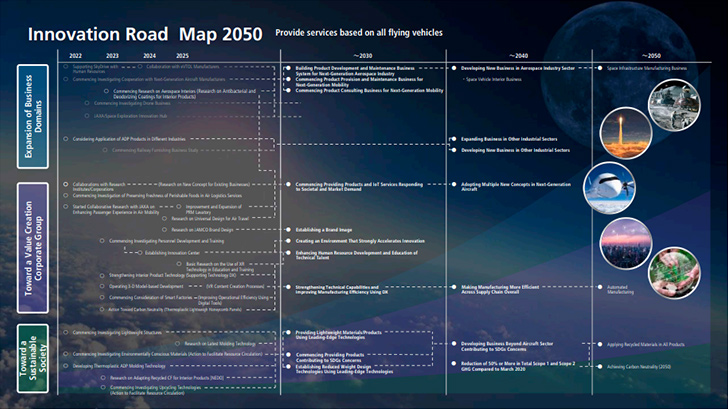

The Technology & Innovation Center, and R&D groups belonging to each Group’s technical departments, have formulated the ideal forms for the products and services that our company will provide in the Innovation Road Map 2050. Based on this, they conduct R&D and prototyping for new products, research, develop, and adopt new technologies, pioneer new markets, and improve and research existing technologies. These activities are categorized into basic research, applied research, and industrialization research according to the stage of development. In practice, the Technology & Innovation Center handles basic and applied research, while each Group handles industrialization research, which is development directly linked to productization. This system drives productization by linking the Technology & Innovation Center and Groups from basic development through to product development.

We contribute to a sustainable society by actively acquiring patents, utility models and other industrial property rights to build up proprietary technology and apply it to products.

We strive to create products and services in a technologycentered world. To this end, JAMCO works to secure digital human resources and foster a corporate culture of innovation so that human resources and organizations can demonstrate their capabilities to the maximum.

In terms of training technical human resources, the Technology & Innovation Center serves as a company-wide learning center for such individuals. It operates and manages technology training programs shared throughout the Company to systematically develop, train, and re-train technical people and help them acquire qualifications and certification.

Additionally, the Aircraft Interiors Group and Aircraft Maintenance and Manufacturing Group work to improve knowledge and expertise through in-house and external education and seminars tailored to the business of each. In the Aircraft Interiors Group, technology training is the basis of product development, and all technical staff are provided with basic education (E-learning, face-to-face instruction) and specialist education in small groups. In the Aircraft Maintenance and Manufacturing Group, knowledge and experience is shared via flow-down training on the various technologies of each aircraft manufacturer.

We will actively engage in initiatives to create innovation by fostering human resources for the future, enerating employment, and developing technologies. We do this through interaction with local schools, support for education and studies at universities, etc., and joint R&D in collaboration with overseas companies, and more.

The research and development groups positioned in our Technology & Innovation Center and in each Group’s technical department have formulated the ideal forms for the products and services our company will provide

in Innovation Road Map 2050. We are conducting research and development and technical development in accordance with this roadmap, and also promoting the education of personnel involved in these activities.