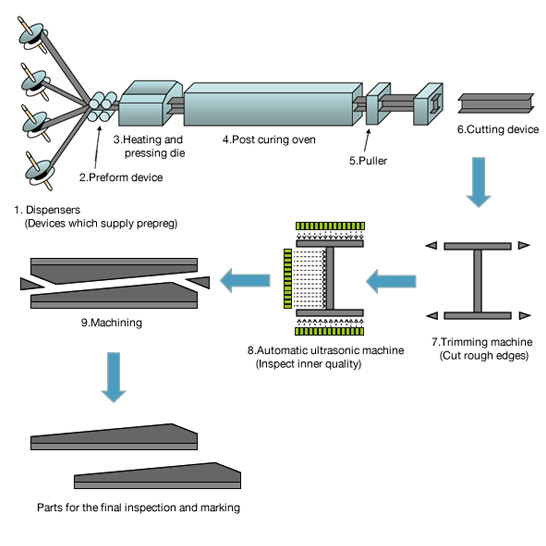

- Several prepreg layers are layered, and set in dispensers.

- Prepreg taken from multiple rolls are layered and formed into preforms with a cross section.

- Profiles are gradually cured when they go through a heating and pressing die.

- Profiles are completely cured when they come out of a post curing oven.

- Entire profiles are intermittently pulled and moved by a puller.

- Profiles are cut into specified lengths by a cutting device.

- Rough edges are deburred using a trimming machine.

- Inner quality of profiles are inspected with using an automatic ultrasonic flaw detector

- Inspected profiles are machined according to required dimensions. (Profiles with H cross section are molded and cut which enables efficient production.)